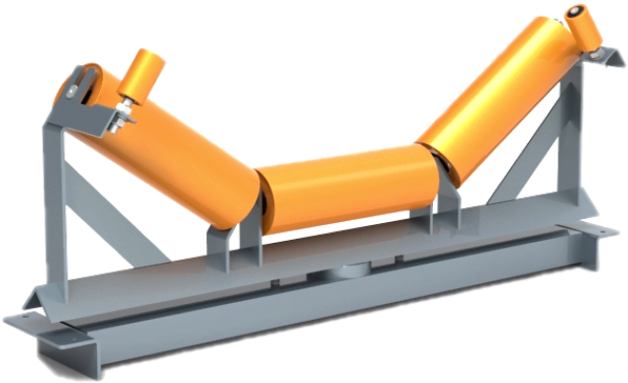

Idlers

Return Bracket

Base Mounted Idlers consists of a single or double steel idler mounted on the two drop brackets. These drop brackets are also known as the return brackets. Among the single or dual steel idlers, the single design is more prevalent in use. Two brackets are secured to either side of the belt conveyor support structure. The Base Mounted Idler is lightweight but still capable of supporting the belt. It ensures no stretching, sagging, and failure of any kind during the idler’s regular functioning. This idler is dustproof and highly durable due to its material constituents. Base Mounted Idler requires less maintenance and low operating cost.

As far as the return side of a conveyor is concerned, the flat return idler is the most common idler. Flat return idlers support the belt in order to prevent stretching, sagging, and failure. These idlers contain a single steel roll mounted on two drop brackets.

Flat Return Idler

Galvanized Machined Idler

Velocity Rollers are the suppliers of hot-dipped Galvanized Machine Idlers. In the galvanizing process, the zinc coat is applied on the idler’s surface to improve its life and durability quite considerably. This process helps in providing the anti-static elements and preventing corrosion in the idlers. These idlers are vital in the conveying process in many industries. Galvanized Machine Idlers support the belt, so the material is conveyed along its full length while preventing the belt from stretching, sagging, and failing. This idler is usable in harsh environments wherein dirt, dust, humidity, and temperature variance exists.

The most expensive part of a conveying system is often the conveyor belt. It’s of prime importance to make sure that the belt is fully functioning and free from damage. That’s what a self-aligning carrying idler does. It ensures that the conveyor belts stay on track, thereby minimizing the chance of severe belt corruption. Self-aligning carrying idlers are concave in shape and restrain the belt from running up and over the conveyor. They also reduce the friction between the idler and belt.

Self Aligning Carrying Idler

Self Cleaning Idler

Self Cleaning Idlers are effective in cleaning up the debris that get collected under the belt conveyor. It has high wear and a rust resistant steel with the hard coating on the surface for long bearing life and noise reduction. This helps in avoiding sticky or gummy carry-back material on the belt. Self-Cleaning Idler is very helpful in belt tracking and also makes sure that there is no need to stop machinery for any maintenance. It is designed for the toughest of applications with its strengthened frame construction. The robustness in its design reduces belt tensions and lowers the power requirements hence incurring lesser operational costs, and no production time is lost.

When visual or magnetic inspections are being conducted, conveyed materials that are not correctly flattened can cause issues. Picking idlers helps spread the material out by using a longer center roll and short concentrator rolls angled at 20°. This makes the inspection or tramps iron detection more effortless and more reliable.

Picking Idler

Carrying Idler

Carrying idlers contain three or more idlers, which then guide the conveyor belt. They are installed along the entire length of the conveyor and found on the carrying-side of the belt. Carrying idlers work so that they keep the belt in the same configuration all along its length. It helps maintain the same cross-sectional area as the belt carries mined materials from their source to the drop-off point. Carrying idlers helps maintain the shape consistency of the belt throughout its journey, thereby improving the stability and carrying capacity.

Inverted V-return idlers are employed to positively track the belt on the return side of the conveyor. They are adjustable and increase the displacement and also the resulting tracking force on the belt. Inverted V-return idlers work on reversing belts, have no swivels, and are sealed for life ball bearings.

Inverted V-Return Idler

Non-Magnetic Carrying

Non-Magnetic Carrying/Impact Idlers are made up of SS 304/316 material. These idlers are also known as Stainless Steel Idlers. It is used for explosive material carrying because of its unique material properties. Non-Magnetic Carrying/Impact Idlers are used in the area where the magnetic field’s impact is relatively high, especially in an underground setting, while compared to most other sites. The anti-corrosion properties of this idler prevent rust from happening for a long time. It increases the life and durability of the idlers. Non-Magnetic Carrying/Impact Idlers have low noise and minimal shaking while conveying material from the source to the drop off point.

Retractable Carrying Idlers contain three idlers for carrying and guiding the belt conveyor loaded with bulk material. It gets installed along the whole length of the conveyor to maintain the same cross-sectional area. This idler is located on the carrying-side of the belt. With the use of the Retractable Carrying Idler, the material is sent from its very source to the drop-off point. These idlers are designed to facilitate the replacement of worn-out or damaged idlers quickly. Retractable Carrying Idler can give the consistency needed for the belt to improve its stability and increase the material carrying capacity.

Retractable Carrying Idler

Garland idlers

Garland idlers consist of 3-roll or 5-roll idlers joined together at the ends of their respective shafts by unique lugs to form a continuous idler chain. The shafts are connected on either side of this chain to an attachment bracket, enabling the idler set to be attached to the conveyor stringer structure. Garland idlers are used mainly on yard conveyors, shiftable conveyors, and dump conveyors.

Impact idlers are used to load areas of the belt where the belt damage is expected owing to the falling material and consistent impacts. They help in absorbing impact forces, thereby preventing damage to the conveyor belt, idler frame, and surrounding structure. Impact idlers help avoid damage to the belt, which is essential since the belts cost a lot to repair and replace. Therefore, they decrease maintenance costs and improve productivity.

Impact Idler

Carrying Transition Idler

Carrying transition idlers are always installed at the loading point of the tail pulley and the drive pulley. The toughing angle should be adjusted as per the transition design of the conveyor. They reduce the belt edge’s tensile force working on the idlers and support the belt between the terminal pulley and the carrying idler of the largest angle used.

Self-aligning return idlers are used to correct the belt tracking and keep it always in a central position. They are used for mining, seaport, storage, cement plants, power plants, steel mills, and chemical plants.

Self-Aligning Return Idler

5 Roller Carrying Idler

5 Roll Carrying Idlers provide significant benefits such as High Load Carrying Capacity.

3 roller offset carrying idlers act as an alternative to inline idlers. They come with many benefits, such as reduced overall height and reduced gap between middle and side rollers. This also reduces the risk of the belt becoming snagged and damaged. They are often used in underground mines and even with thin belt carcasses.